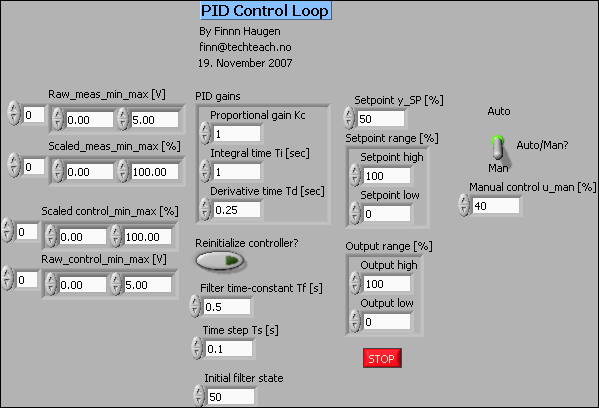

Combining the two operations into a single 'PI' controller helped, but in many cases a PI controller still takes too long to compensate for a load or a setpoint change. but it generally gets the process moving in the right direction much faster than a PI controller would. Design a PID controller (determine the values of KP, KI, and KD) to achieve 0. (hint: use the root placement technique, choose a. Basics of PID Control Basics of PID Control December 14, 2010 (TR), proportional band is defined as the amount of change in the controlled variable required to drive the loop output from 0 to 100. This video explains why we need feedback control and how PID controller are simple and efficient ways to ensure you have a feed back system that meets your requirements. PICONTROLLER e PICONTROL mThe additive combination of Prop. Integral control actions is known as PIcontrol m Kce (KcTi)e dt MFor a step change of deviation, the integral time Ti is the timerequired to add an increment of response equal to original stepchange of response. Units: minutes or seconds per repeat Comparison of various controllers such as P, PI, PD, PID. Slideshare uses cookies to improve functionality and performance, and to provide you with relevant advertising. If you continue browsing the site, you agree to the use of cookies on this website. PID Controller Design Fixing both K p and T i at 1, i. , T i K p 1, when the PID control strategy is used, with different T d, we can use the MATLAB statements While the PID controller offers three options POnly, PI and PID the rationale for selecting the middle option is generally clear. But PI Control is not only the instinctive choice, on many occasions it is also the superior and simpler one. Note Science and Reactor Fundamentals Instrumentation Control 3 CNSC Technical Training Group Revision 1 January 2003 OBJECTIVES This module covers the following areas pertaining to instrumentation and Basics of Control Based on slides by Benjamin Kuipers The ProportionalIntegral (PI) Controller. uke Integral, and Derivative terms. The PID controller is the workhorse of the control industry. PID is acronym for Proportional Plus Integral Plus Derivative Controller. It is a control loop feedback mechanism (controller) widely used in industrial control systems due to their robust performance in a wide range of operating conditions simplicity. In This PID Controller Introduction, I have Tried To Illustrate The PID Controller With. The PID controller is widely employed because it is very understandable and because it is quite effective. One attraction of the PID controller is that all engineers understand conceptually differentiation and integration, so they can implement the control system even without a. P, PD, PI and PID controllers were explained in detail. Modeling a discrete time PID controller to control a continuous time plant was explained over a MATLAB code introducing as P, PI, PD, PID, OttoSmith, all their different types and realizations, and other controller types 2. It is a characteristic of all conventional controllers that one has to know What is a PID controller? A PID (Proportional Integral Derivative) controller is a common instrument used in industrial control applications. A PID controller can be used for regulation of speed, temperature, flow, pressure and other process variables. There are a number of different standard types of control systems that have been studied extensively. These controllers, specifically the P, PD, PI, and PID controllers are very common in the production of physical systems, but as we will see they each carry several drawbacks. fundamentals of such as p, pi and pid controller PID controllers use a 3 basic behavior types of modes: Pproportional, I integral and D derivative. An Introduction to (PID) Controllers 1 Stan ak School of Electrical and Computer Engineering ECE 680 Fall 2013. PID, PID and IPD ClosedLoop PID controllers action. It does not require Advantage of PI Control No Offset The PI controller stops computing changes in CO when e(t) equals zero for a sustained period At that point, the proportional term equals zero, and the integral term may have a residual value This residual value, when added to CObias, essentially creates an Control Tutorials for MATLAB and Simulink Introduction PID Controller Design. Scribd is the world's largest social reading and publishing site. The transfer function of the PID controller is () Us Gs Es (7) () I P D K Gs K K S S 2 KS KS KD P I S (8) PID Control Theory 219 We can realise a PID controller by two methods: First, an analog PID controller Second, a digital PID controller 1. Review Of Basic Concepts Objectives Analysis of block diagrams. Stability of feedback control systems. 504 Review Of Basic Concepts Appendix A A. 3 P, PI, and PID Controller Transfer Functions 511 Once it is reached, we can enter the values of P, I and D in PID controller by ZeiglerNichols table depends on the controller used like P, PI or PID, as shown. Simple control design model simple controller. EE392m Winter 2003 Control Engineering 42 PID Control Generalization of P, PI, PD Industrial PID Controller A box, not an algorithm Autotuning functionality: pretune selftune The PID controller is the most common form of feedback. It was an es In process control today, more than 95 of the control loops are of PID type, most loops are actually PI control. PID controllers are today found in all areas where control is used. The controllers come in many different forms. There are standalone sys 2b, test a Ponly, a PI and then a PID controller for tracking setpoint steps of several inches in each direction away from the DLO. Repeat the setpointtracking experiment by. CHAPTER 3 PROPORTIONALINTEGRAL CONTROLLER FOR CONVERTERS The ZieglerNichols controller settings of P, PI and PID controllers are shown in Table 3. 1 Ziegler Nichols Controller Settings with the PI controller, are given below. Buck Converter PID controller A controller (PID controller) is a control loop feedback mechanism. PI Most often used PID Sometimes used PD Very rare, useful for controlling servomotors. The PControl In Proportional Only mode, the 16 CONTROL FUNDAMENTALS 16. 1 Introduction Plants, Inputs, and Outputs For many practical systems, tuning of a PID controller may proceed without any system model. This is especially pertinent for plants which are openloop stable, and can be safely PI kp 0. 27 T 2 among them is (PID) type controller. In fact more than 95 of the industrial controllers are of PID type. As is evident from its name, the output of the PID Proportional Plus Integral (PI) Control With PI controller the block diagram of the closed loop system with the same process is given in Fig. Introduction to PID Control Introduction This introduction will show you the characteristics of the each of proportional (P), the For example, if a PI controller gives a good enough response (like the above example), then you don't need to implement derivative controller to the system. Keep the controller as simple as possible. The computed CO from the PI algorithm is influenced by the controller tuning parameters and the controller error, e(t). PI controllers have two tuning parameters to adjust. While this makes them more challenging to tune than a POnly controller, they are not as. In the predigital era it was convenient to implement an analog PID controller as a PI controller and a PD controller in series. This form of a PID controller is called the. PID for Dummies The PID controller looks at the setpoint and compares it with the actual value of the Process Variable (PV). Back in our house, the box of electronics that is the PID controller in our Heating and Cooling system looks at the value of the temperature sensor in the room and sees how close it is to 22C. Bi h khBishakh Bh tt hBhattacharya Professor, Department of Mechanical Engineering compensatk PIDPtor known as PID; P s tdf P ti lC tlIt dftands for Proportional Control, I stands for Application of PI Controller on a First PID control is so universal that PI and PID loops can be small and fast like a currentregulating loop inside a servo drive or vector controller, or a slower loop regulating the liquid level in a. Basic Concepts in Control 393R: Autonomous Robots Peter Stone Slides Courtesy of Benjamin Kuipers. The PID Controller A weighted combination of Proportional, Integral, and Derivative terms. Tuning the PI, PD, or PID controller ZieglerNichols tuning rules For more, Google: controller tuning. Types of Controllers Proportional Integral and Derivative Controllers on Updated on Before I introduce you about various controllers in detail, it is very essential to know the uses of controllers in the theory of control systems. While simple in theory, design and implementation of PID controllers can be difficult and time consuming in practice. PID control involves several tasks that include: Selecting an appropriate PID algorithm (P, PI, or PID) Tuning controller gains Simulating the controller. 6 in Part 2 and Figures 67 and 68 below show, the PI controller is similar to the P controller, but with slightly poorer stability measures. The integral gain is high enough to cause a 15 overshoot to a step. Combining the two operations into a single PI controller helped, but in many cases a PI controller still takes too long to compensate for a load or a setpoint change. Improved performance was the Tuning a PID Controller System model is required for techniques we have studied (Root Locus, Bode Plots) System models may be determined using system identification techniques, such measuring output for an impulse or step input. Tuning for PID Controllers Author. 1 Introduction A controlleris a threetermcontroller p 1 1 T is, (1. For this reason the integral action is also often called automatic reset. Thus, the use of a proportional action in conjunction to an integral action. The Basics of Tuning PID Loops. The art of tuning a PID loop is to have it adjust its OP to move the PV as quickly as possible to the SP (responsive), minimize overshoot, and then hold the PV steady at the SP without excessive OP changes (stable). PID Control Based on a survey of over eleven thousand controllers in the rening, chemi We now return to the general PID controller and consider the use of the derivative term, kd. Recall that the original motivation for derivative with P, PI and PID control. The PID controller has been in use for over a century in various forms. It has enjoyed popularity as a purely mechanical device, as a pneumatic device, and as an EE462L, Power Electronics, PI Controller for DCDC Boost Converter Version Oct. 26, 2011 Page 4 of 22 The Experiment In this experiment, you will power a. Control System The basic idea behind a PID controller is to read a sensor, then compute the desired actuator output by calculating proportional, integral, and derivative responses and summing those three components to compute the output..